What is Control Exhaust Valve and How Does it Work?

In the world of fluid control systems, the Control Exhaust Valve plays a crucial role. Renowned expert Dr. Emily Johnson, a leading authority on industrial valve engineering, states, "The efficiency of any system often hinges on the performance of its control exhaust components." This emphasizes the importance of understanding how these valves operate.

A Control Exhaust Valve regulates the flow of gases during operation. It is vital for preventing excessive pressure build-up in various applications. Imagine a pump in a hydraulic system; the Control Exhaust Valve ensures that excess fluid is safely released, maintaining balance. If not managed correctly, these systems can face severe issues, leading to costly repairs.

Despite their significance, many overlook the intricate design and functionality of Control Exhaust Valves. The mechanisms can be complex, involving electronic sensors and pneumatic controls. Misunderstandings around their operation can lead to inefficiencies. Awareness of their function is essential for optimal system performance. Failing to grasp their importance can result in major setbacks.

Understanding the Basics of Control Exhaust Valves in Industrial Systems

Control exhaust valves play a crucial role in industrial systems. They help regulate the flow of exhaust gases. This optimization is essential for maintaining efficiency and ensuring safety. According to a recent report by the International Society of Automation, improper valve function can lead to energy losses of up to 30%. Such statistics underscore the importance of these components in operational settings.

Understanding how control exhaust valves work is key. They typically use pneumatic or electric actuators. These actuators adjust the valve opening based on the system's needs. However, challenges can arise. For instance, accumulated residue can obstruct valve movement. Regular maintenance is vital, yet many facilities overlook this. Data suggests that unmonitored valves can increase operational costs significantly. This can create opportunities for improvement.

Another pressing issue is the discrepancy in valve performance monitoring. Many systems do not have effective tracking mechanisms. A study showed that 40% of companies do not use real-time data analytics for these valves. This gap could lead to inefficiencies and increased downtime. The need for better monitoring tools is evident for optimizing control exhaust valve operations.

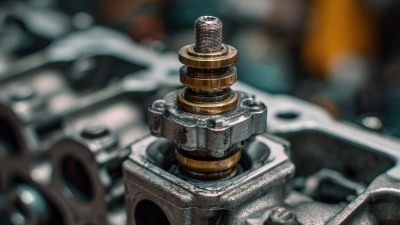

Functionality and Mechanism: How Control Exhaust Valves Operate

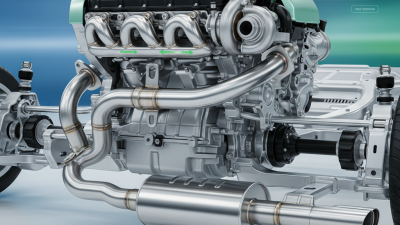

Control exhaust valves play a crucial role in regulating airflow in various systems, particularly in engines. They help manage exhaust gases, which can improve efficiency. These valves respond to engine demands, adjusting the flow of exhaust gases based on performance needs. This dynamic adjustment is key to optimizing operation.

The mechanism of control exhaust valves is fascinating. When the engine reaches specific conditions, sensors trigger the valve to open or close. This action directly influences backpressure within the exhaust system. Proper backpressure is necessary for engine efficiency, power, and emissions control. However, if the system isn't calibrated correctly, problems can arise. Miscalculations can lead to poor performance.

Maintaining control exhaust valves is essential, yet it's often overlooked. Regular inspections can prevent failure. A faulty valve can cause a drop in efficiency or increase emissions, ultimately affecting the entire system's performance. Each valve must operate smoothly. Minor issues can snowball into significant problems. Addressing these concerns promptly is crucial for the health of an engine.

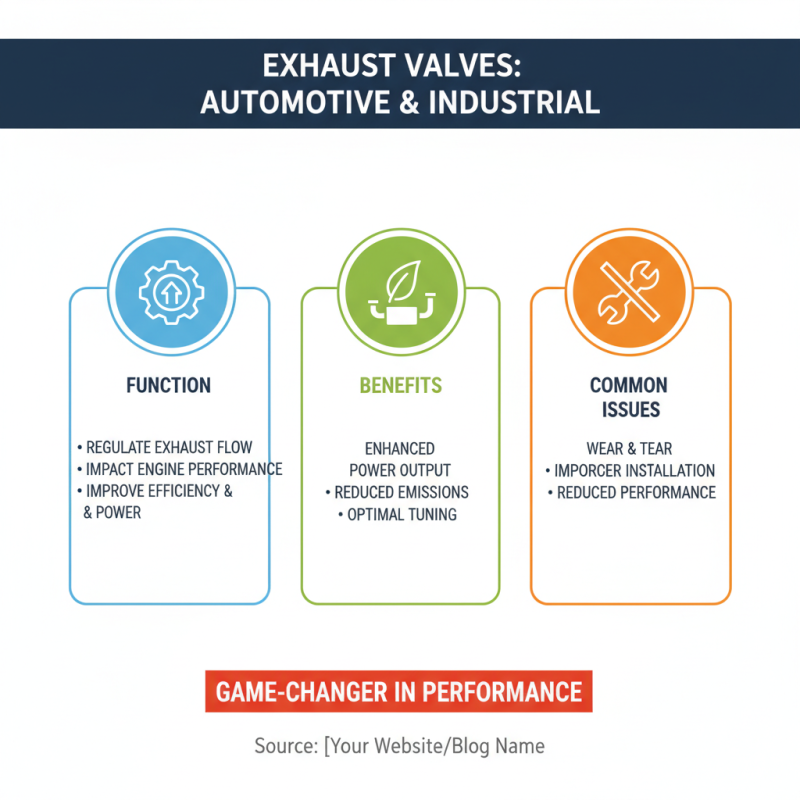

Key Components of Control Exhaust Valves and Their Roles

Control exhaust valves play a crucial role in automotive and industrial applications. These valves help regulate exhaust flow, impacting engine performance and efficiency. They can enhance power output and reduce emissions when functioning correctly. A well-designed valve can be a game-changer in performance tuning. However, not all valves perform optimally; issues can arise from wear and improper installation.

Key components of control exhaust valves include the actuator, valve body, and sensors. The actuator is responsible for opening and closing the valve. It can be pneumatic or electric, affecting response times. The valve body houses the mechanical parts and influences the exhaust flow characteristics. Sensors monitor exhaust pressure and temperature, providing data for adjustments. If any component fails, the system may not function correctly. Some users overlook these details, which often leads to inefficiencies.

Maintenance is essential for these components. Regular inspections can prevent failures that result from dirt or corrosion. Ignoring signs of wear can lead to significant performance issues. Users must assess their systems regularly. An occasional check-up can make a big difference, ensuring each component works together seamlessly. While modern technology often simplifies this process, human error always poses a risk.

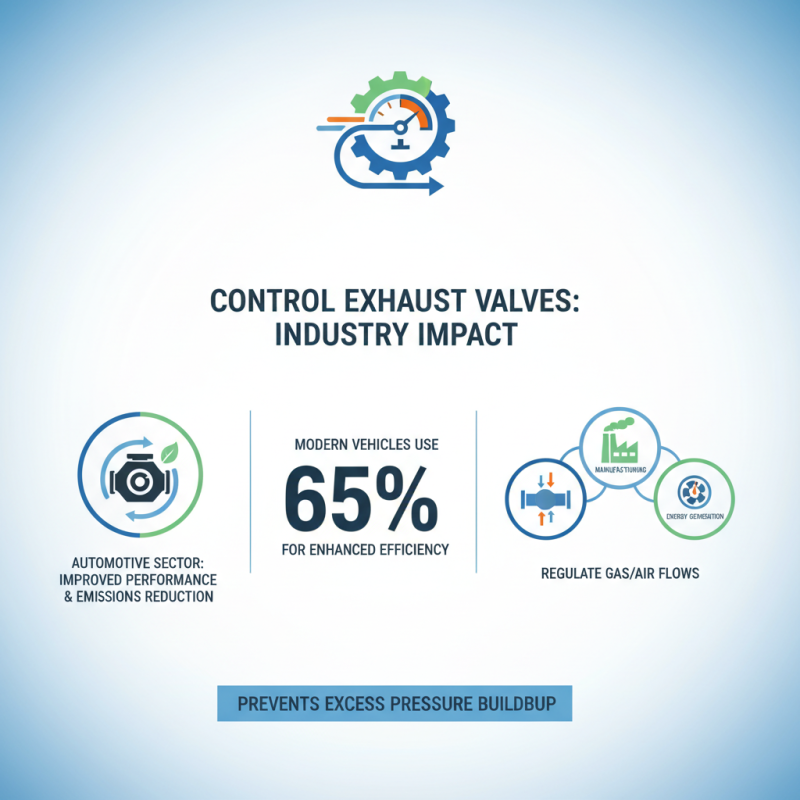

Applications of Control Exhaust Valves in Various Industries

Control exhaust valves play a crucial role across multiple industries. They regulate gas or air flows, preventing excess pressure buildup. In the automotive sector, these valves improve engine performance and reduce emissions. According to a recent report, nearly 65% of modern vehicles utilize control exhaust valves for enhanced efficiency.

In the energy sector, control exhaust valves are equally vital. They help maintain optimal performance in gas turbines. When correctly implemented, they can achieve efficiency rates exceeding 90%. However, issues can arise. Improper calibration may lead to energy losses and increased operational costs. This highlights the need for regular maintenance and monitoring.

In manufacturing, control exhaust valves ensure safety in processes involving hazardous materials. Their malfunction could result in leaks or explosions. A study indicated that about 30% of manufacturing incidents are linked to valve failures. This emphasizes the importance of rigorous quality control and regular equipment testing to prevent accidents. Careful evaluation and consistent improvements are essential for reliability and safety.

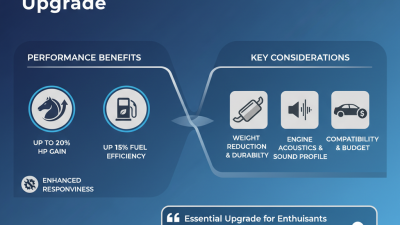

Performance Metrics: Efficiency and Reliability in Control Exhaust Valves

Control exhaust valves play a crucial role in various mechanical systems. Their main function is to manage the flow of exhaust gases. This regulation is vital in optimizing operational efficiency. A well-functioning valve can greatly enhance system performance and reliability.

However, the performance of control exhaust valves hinges on efficiency metrics. An efficient valve minimizes energy loss. It allows for better engine performance while reducing emissions. This balance is essential in today's eco-conscious world.

Tips for ensuring peak valve performance include regular maintenance checks. Small issues can lead to significant performance drops. Monitor the valve's response time carefully. Delays might indicate wear and need for replacement.

Another tip is to evaluate the installation conditions. Improper alignment can impair efficiency. Take time to assess the system regularly. A fluid operation will save time and resources in the long run. Reflect on these factors to enhance performance metrics and reliability.

What is Control Exhaust Valve and How Does it Work? - Performance Metrics: Efficiency and Reliability in Control Exhaust Valves

| Metric |

Value |

Unit |

| Flow Rate |

250 |

L/min |

| Max Pressure |

200 |

bar |

| Response Time |

15 |

ms |

| Temperature Range |

-40 to +120 |

°C |

| Cycle Life |

1,000,000 |

cycles |

| Efficiency |

98 |

% |

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number