What is Stainless Steel Exhaust Tubing and How Does it Enhance Vehicle Performance?

Stainless Steel Exhaust Tubing plays a crucial role in enhancing vehicle performance by optimizing exhaust flow and reducing backpressure. According to a report by the Specialty Equipment Market Association (SEMA), aftermarket exhaust systems, predominantly made from stainless steel, can increase horsepower by an average of 5-10% across various vehicles.

The superior corrosion resistance and durability of stainless steel over conventional mild steel allow for longer-lasting exhaust systems, which is critical in performance applications where heat and chemical exposure can tax materials.

Furthermore, the smooth interior surface of stainless steel tubing minimizes turbulence, allowing for a more efficient expulsion of exhaust gases. This performance upgrade is not only significant for enthusiasts looking for gains in speed and efficiency but also aligns with a growing trend towards vehicle modifications that emphasize both longevity and performance.

Stainless Steel Exhaust Tubing plays a crucial role in enhancing vehicle performance by optimizing exhaust flow and reducing backpressure. According to a report by the Specialty Equipment Market Association (SEMA), aftermarket exhaust systems, predominantly made from stainless steel, can increase horsepower by an average of 5-10% across various vehicles.

The superior corrosion resistance and durability of stainless steel over conventional mild steel allow for longer-lasting exhaust systems, which is critical in performance applications where heat and chemical exposure can tax materials.

Furthermore, the smooth interior surface of stainless steel tubing minimizes turbulence, allowing for a more efficient expulsion of exhaust gases. This performance upgrade is not only significant for enthusiasts looking for gains in speed and efficiency but also aligns with a growing trend towards vehicle modifications that emphasize both longevity and performance.

Definition and Composition of Stainless Steel Exhaust Tubing

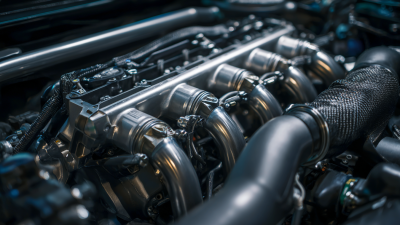

Stainless steel exhaust tubing is a crucial component in automotive exhaust systems, known for its durability and resistance to corrosion. It is primarily composed of iron, chromium, and nickel, which together form an alloy that can withstand high temperatures and harsh environmental conditions. The inclusion of chromium provides stainless steel with its characteristic sheen and enhances its ability to resist rusting and staining, making it a popular choice for performance vehicles.

Stainless steel exhaust tubing is a crucial component in automotive exhaust systems, known for its durability and resistance to corrosion. It is primarily composed of iron, chromium, and nickel, which together form an alloy that can withstand high temperatures and harsh environmental conditions. The inclusion of chromium provides stainless steel with its characteristic sheen and enhances its ability to resist rusting and staining, making it a popular choice for performance vehicles.

When considering an upgrade to stainless steel exhaust tubing, it's essential to look at the specific grades available, such as T304 and T409. T304, for instance, is renowned for its high resistance to corrosion and is often used in high-performance applications. On the other hand, T409 is more budget-friendly and provides decent corrosion resistance, suitable for less demanding vehicles.

Tips: When selecting stainless steel exhaust tubing, always check for quality certifications and proper fittings to ensure a seamless installation. Additionally, opting for mandrel-bent tubing can enhance airflow compared to standard crush-bent options, ultimately improving vehicle performance.

Advantages of Stainless Steel Over Traditional Materials

Stainless steel has emerged as a preferred material in automotive applications, particularly in exhaust tubing, due to its superior properties compared to traditional materials. One of the notable advantages is its excellent resistance to corrosion, which is paramount in exhaust systems that regularly encounter high temperatures and corrosive gases. According to a study by Munich University and the supplier Outokumpu, the corrosion durability of stainless steel structures extends the lifespan of vehicle components, resulting in better overall performance and reduced maintenance costs.

Another significant advantage of stainless steel is its strength-to-weight ratio, which plays a critical role in enhancing vehicle efficiency. Advanced lightweight materials, including high-strength stainless steels, offer substantial weight savings without compromising structural integrity. Research highlights that incorporating lightweight materials in automotive design can lead to improved fuel efficiency and reduced emissions, aligning with industry advancements towards sustainable solutions. Furthermore, innovations such as 3D printed stainless steel components allow for precise engineering and further enhance performance characteristics, demonstrating the ongoing evolution of materials in the automotive sector.

Impact of Stainless Steel Exhaust Tubing on Engine Performance

Stainless steel exhaust tubing plays a pivotal role in enhancing vehicle performance by improving exhaust flow and reducing back pressure. When exhaust gases are expelled more efficiently, the engine can breathe easier, which results in improved horsepower and torque. This efficiency is especially noticeable in high-performance vehicles where every bit of power counts. Moreover, stainless steel is resistant to corrosion and high heat, ensuring longevity and consistent performance over time.

Stainless steel exhaust tubing plays a pivotal role in enhancing vehicle performance by improving exhaust flow and reducing back pressure. When exhaust gases are expelled more efficiently, the engine can breathe easier, which results in improved horsepower and torque. This efficiency is especially noticeable in high-performance vehicles where every bit of power counts. Moreover, stainless steel is resistant to corrosion and high heat, ensuring longevity and consistent performance over time.

Tips: When considering upgrading to stainless steel exhaust tubing, ensure it is a proper fit for your vehicle's make and model. A well-designed system can prevent unwanted vibrations and noise while maximizing flow. Additionally, pairing the exhaust upgrade with a tuned engine management system can lead to optimal performance gains.

The impact of stainless steel exhaust tubing extends beyond just performance; it also affects sound. A quality exhaust system can produce a deeper, more aggressive sound without being overly loud, providing a satisfying driving experience. This auditory feedback can enhance the overall enjoyment of driving, especially in a sportier vehicle.

Tips: While aesthetics and sound are important, always prioritize performance features when selecting exhaust tubing. Look for systems that offer mandrel bends for better flow, and consider adding a high-flow catalytic converter for even greater gains.

Role of Exhaust Tubing in Enhancing Vehicle Efficiency

Stainless steel exhaust tubing plays a crucial role in enhancing vehicle efficiency, primarily by improving exhaust flow. By allowing exhaust gases to exit the engine more smoothly, stainless steel tubing reduces back pressure, which can significantly bolster engine performance. With less resistance, the engine can breathe easier, leading to increased horsepower and torque. This improvement not only enhances the driving experience but also can contribute to better fuel efficiency, making your vehicle perform at its best.

When considering upgrades, opting for stainless steel could be a game-changer. Tips for selecting the right tubing include ensuring that the diameter matches your vehicle's specifications to optimize exhaust flow. Additionally, look for mandrel-bent tubing, which maintains a smooth interior surface and prevents turbulence, further enhancing efficiency. Regularly inspect the exhaust system for leaks, which can affect engine performance; a well-maintained system ensures that you're getting the most out of your vehicle's powertrain.

Impact of Exhaust Tubing Material on Vehicle Performance

Maintenance and Longevity of Stainless Steel Exhaust Systems

Stainless steel exhaust systems are praised for their durability and resistance to corrosion, making them an ideal choice for vehicle enthusiasts. To maintain these systems and ensure longevity, regular inspections are essential. Look for signs of wear, such as rust or damage at the joints and connections, to catch potential issues early. Additionally, ensuring that your exhaust system is securely mounted can prevent unnecessary vibrations that may lead to premature wear.

When it comes to cleaning your stainless steel exhaust, it’s important to avoid abrasive cleaners that can scratch the surface. Instead, use a gentle soap and water solution, followed by a specialized stainless steel polish. This not only enhances the appearance but also creates a protective layer that combats rust and grime buildup.

Another effective tip for maximizing the lifespan of your stainless steel exhaust system is to avoid short trips whenever possible. Frequent short drives can prevent the exhaust system from reaching its optimal temperature, leading to condensation buildup inside the pipes, which can promote corrosion over time. By being mindful of your driving habits and performing regular maintenance checks, you can help your stainless steel exhaust system perform at its best for many years to come.

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number

Stainless steel exhaust tubing plays a pivotal role in enhancing vehicle performance by improving exhaust flow and reducing back pressure. When exhaust gases are expelled more efficiently, the engine can breathe easier, which results in improved horsepower and torque. This efficiency is especially noticeable in high-performance vehicles where every bit of power counts. Moreover, stainless steel is resistant to corrosion and high heat, ensuring longevity and consistent performance over time.

Stainless steel exhaust tubing plays a pivotal role in enhancing vehicle performance by improving exhaust flow and reducing back pressure. When exhaust gases are expelled more efficiently, the engine can breathe easier, which results in improved horsepower and torque. This efficiency is especially noticeable in high-performance vehicles where every bit of power counts. Moreover, stainless steel is resistant to corrosion and high heat, ensuring longevity and consistent performance over time.