The performance of automotive exhaust systems has gained significant attention in recent years, particularly when comparing stainless steel to other materials. The Global Stainless Steel Seamless Pipes Market is projected to reach USD 5.15 billion by 2030, highlighting the growing demand for durable and high-performance components in the automotive industry.

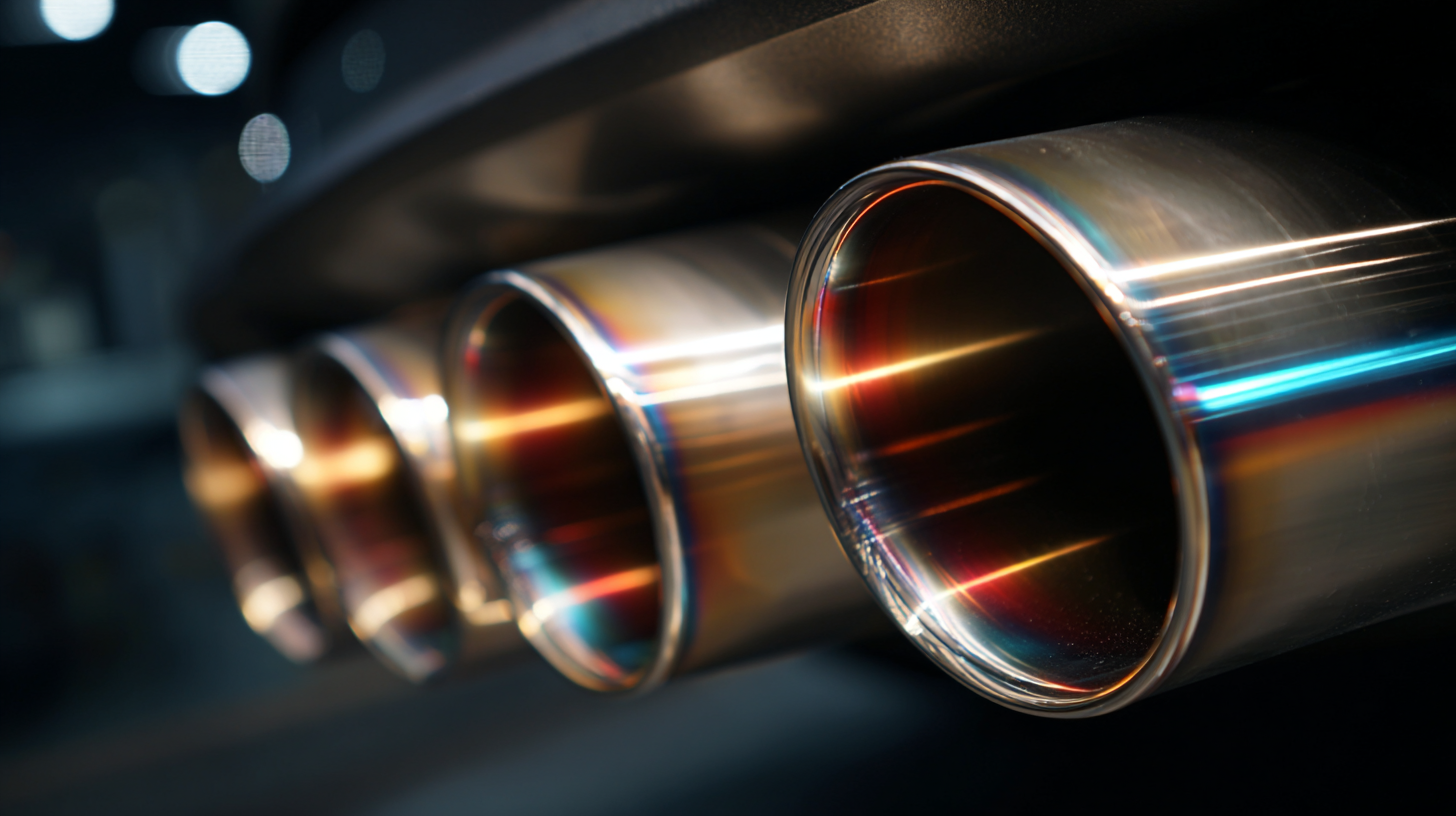

Stainless steel is favored due to its excellent resistance to corrosion, heat, and mechanical stress, making it an ideal choice for exhaust tubing which must withstand extreme operating conditions.

Furthermore, the Stainless Steel Welded Pipe Market is forecasted to reach USD 34.0 billion by 2035, with a remarkable compound annual growth rate (CAGR) of 5.0% between 2025 and 2035. This growth reflects not only the material's longevity and performance in harsh environments, but also its superior ability to enhance engine efficiency compared to traditional exhaust materials.

In comparative studies, stainless steel tubes have shown a marked improvement in exhaust flow and reduced back pressure, thereby optimizing engine performance. These factors underline the significant role stainless steel plays in advancing automotive technologies.

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number